Reduce heat loss and stabilize process temperatures by wrapping complex geometries with custom-fit removable blankets. Lower fuel use and keep surfaces at safer touch temperatures without sacrificing maintenance access.

Custom Removable Insulation Blankets

Fast, Safe, Built for Extreme Heat

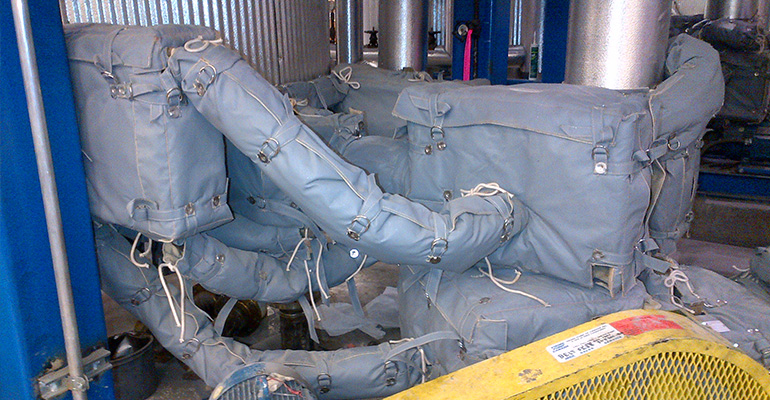

ISO Blanket’s custom removable insulation blankets deliver precision-fit thermal control for real-world operations. Engineered to handle extreme service—up to 3000°F (1650°C) when specified with high-temperature materials—they wrap valves, flanges, pumps, turbines, and irregular geometries without compromising access. The result is reliable heat conservation in tough environments, from process plants to cold-weather sites.

Installation and removal are fast and tool-less, so technicians can expose equipment for inspection in minutes, not hours. Because each blanket is reusable and easy to refit, you cut downtime, lower labour costs, and simplify routine maintenance compared to traditional hard insulation or one-time wraps. Over multiple service cycles, that efficiency compounds into a lower total cost of ownership.

Built for the plant floor, these blankets add a layer of protection from heat and chemical exposure, helping to shield adjacent components while reducing touch temperatures for personnel. The improved access and thermal control contribute to a safer work environment—minimizing burn risk, supporting compliance goals, and keeping crews productive even in demanding conditions.

Installation and removal are fast and tool-less, so technicians can expose equipment for inspection in minutes, not hours. Because each blanket is reusable and easy to refit, you cut downtime, lower labour costs, and simplify routine maintenance compared to traditional hard insulation or one-time wraps. Over multiple service cycles, that efficiency compounds into a lower total cost of ownership.

Built for the plant floor, these blankets add a layer of protection from heat and chemical exposure, helping to shield adjacent components while reducing touch temperatures for personnel. The improved access and thermal control contribute to a safer work environment—minimizing burn risk, supporting compliance goals, and keeping crews productive even in demanding conditions.

Core applications

-

Heat Conservation on Hot Equipment

-

Freeze Protection / Cold-Serviceheat-traced options to −60 °C / −76 °F Prevent freeze-ups on lines and instruments in harsh climates with blankets designed to integrate heat tracing. Maintain operability through extreme cold while allowing fast removal for inspection.

-

Employee Personal Protectionshield from hot surfaces and radiant heat Create cooler, safer work zones by insulating burn hazards and reducing radiant exposure. Removable designs let crews access equipment quickly while maintaining safety barriers.

-

Sound & Vibration Controlthermal + acoustic dampening Use quilted, absorptive builds to cut noise alongside thermal losses in loud industrial areas. Improve comfort and communication without adding separate acoustic systems.

-

Chemical & Harsh Environmentshigh-temp silica/ceramic systems Select media and facings engineered for both extreme heat and chemical resistance. Ideal for refineries, chemical plants, and anywhere splash, fumes, or corrosives are present.

Outcomes & buyer benefits

-

Quick Access, Shorter Downtimeminutes, not hours Tool-less removal means inspections and repairs start sooner and finish faster. You return equipment to service quickly and reduce outage costs.

-

Lower Total Installed Costversus redo-and-re-lag every cycle Reusable blankets avoid the recurring labour and material waste of stripping and reapplying hard insulation. Savings compound over multiple maintenance events.

-

Safety & Compliance — cooler touch tempsCSA/FM/UL options on traced systems By lowering surface temperatures and containing heat, blankets help reduce burn risk and support safety goals. Heat-traced builds can be specified to recognized approvals when required.

-

Durable, Reusable Assetseason after season Engineered to withstand industrial wear, blankets can be redeployed across maintenance cycles and changing seasons. That durability protects your investment and simplifies planning.